What is Data Logging?

Freedom from Manual Data Entry

Freedom from Manual Data Entry

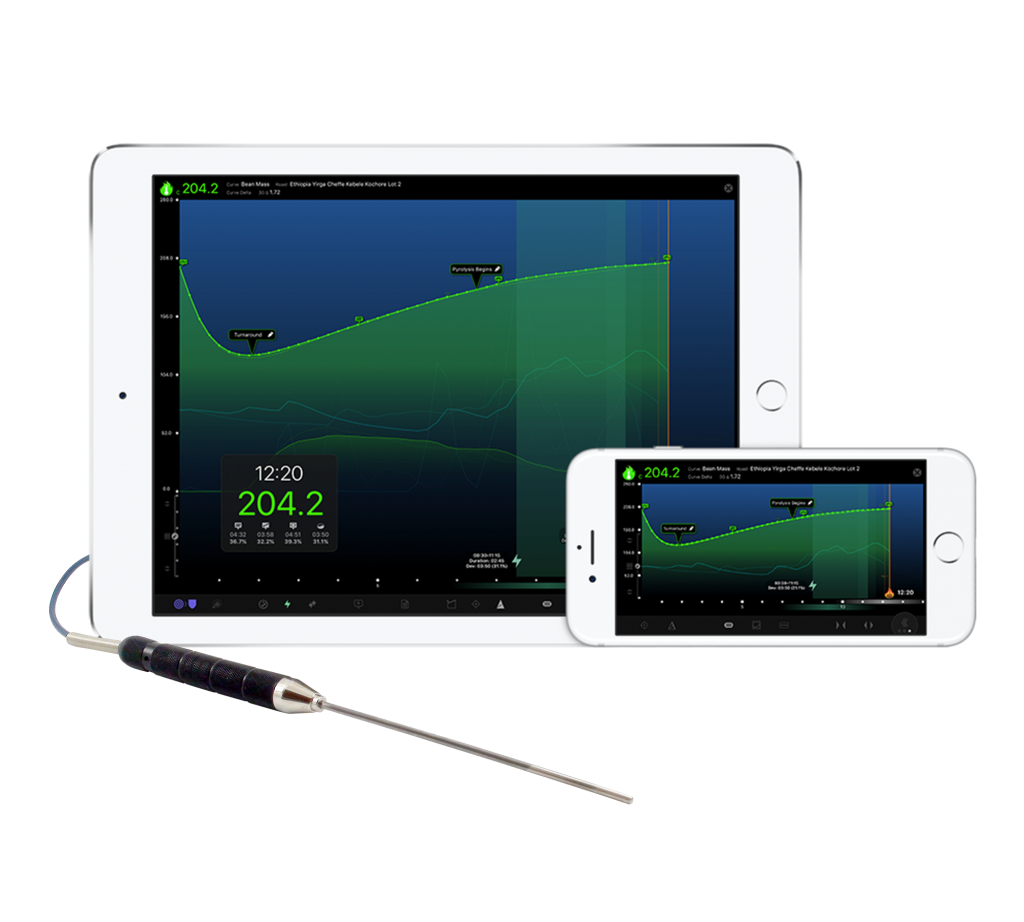

Roastmaster gives you the freedom to create any number of Curves in a roast. Reading curves store temperatures, while Control curves store machine settings, such as air flow, gas pressure or heat. Curves are graphed in both the Roast Console and the Roast Analyzer.

Without the Data Logging option and hardware, you must enter values manually during a roast by selecting the appropriate curve, then tapping the digital readout to enter a value. The value you enter will be recorded in the curve at the appropriate time in the roast.

Hands-free Roasting

The Data Logging option removes the burden of manual data entry for temperature Reading curves. With the appropriate hardware, you simply create Probe definitions in Roastmaster that link to physical thermocouples inserted in your roaster.

Once these probes are defined, you simply link them to your Reading curves in a roast. When a Reading curve is bound to a Probe, the roasting console and analyzer will report the probe’s exact temperature in real time, and automatically record temperatures in the curve throughout the duration of the roast.

In order to use data logging, you will need the following:

- A roaster that can be safely modified to accept a thermocouple

- One of the supported probe hardware configurations (see Getting Started With Data Logging)

- The Roastmaster Data Logging option

Creating Reading Curves in a Roast

- In a new roast, tap the curve button near the roast gauge, and choose “Create New Curve”

- Set the curve type to “Reading”

- Tap the “Bind To” field, and choose the appropriate probe

- Tap save

Back in the roast console, tap the graph to select the appropriate curve. Roastmaster will display its real-time temperature as it changes. Once the roast has begun, Roastmaster will store this temperature data to your curve for the duration of the roast.

If you’re using multiple probes, you can tap the graph to toggle the selected curve to monitor different probe temperatures at different times in the roast, or launch the Roast Analyzer and enable the Roast HUD and Labels features to monitor the temps of all curves simultaneously.

When the roast is complete, you can tap the actions button in the roast console toolbar, and choose “Create Profile from this Roast”. The curves you enable in “Reference Curves” will be saved with the new profile for targeting curves. The curves you enable in “Data Curves” will become curve templates that will spawn new, blank curves in each roast that uses this profile–already bound to your probe, and ready for logging new data.

I want to set up the data logging exactly like you have in the “ROASTMASTER DATA LOGGING WITH PHIDGET TEMPERATURE SENSOR AND LAPTOP HOST” example. I even have the same Quest M3 roaster. How did you install the thermocouples into the roaster? Did you find some aftermarket pieces that screw into the thermometer ports?

Hi Benjamin

In the states, metric parts are hard to come by. I ordered them from a guy named Eric Svendson. Nice guy – he has a parts list here… http://users.rcn.com/erics/Quest_Thermocouples_03.pdf

I didn’t order the fancier compression fittings (he was out of them at the time). Instead, I just ordered 2 of the M8 screws drilled for 1/8″ probes to fit my thermocouples. If you go this route, I advise you do something to keep the probes from accidentally sliding in too far and hitting the drum tines. I used foil HVAC tap wrapped around the probes at the proper depth – works great for me.

Good luck! Let me know if you have other questions.

Danny

Hi Danny,

First up, I’m in Cape Town, South Africa. Hardware is an issue. I use a Toper Cafemino (gas) roaster (http://www.cafemino.com/e-cafemino-gaz.html) and have been using standard roasting sheets to track my roasts. I’m really keen on getting your App, but I want to know if my roaster is suited to also getting the data logging option. My roaster is in a fixed location so just attach to my laptop directly. Anyhow, I’m not really that technically minded so I cannot say whether the Thermocouple on my roaster will hook up to the phidget temperature sensor. I’m not sure there’s enough info on the Toper website but I can send you the pdf document that deals with the thermocouple specifications. My confusion stems from the index suggesting a J-type and K-type compatibility but in the manual itself it only describe the J-type. Are you able to confirm?

Thanks,

Philip

Hi Philip

Not sure if you’re referring to your Cafemino’s documentation or Roastmaster’s documentation, but Roastmaster will accept either a J or K style thermocouple with Phidgets hardware. Setting the probe type is a simple preference setting in the probe details view in the app.

In the foreseeable future, the only option for J type thermocouples in Roastmaster will be Phidgets. I’m submitting an update tomorrow that will provide support (if approved by Apple) for another piece of hardware, but that is K style only. The end result in any case, though, is the same – all that needs to happen from Roastmaster’s perspective is that the Phidget hardware be wired to a thermocouple, so that part is very straightforward.

Mod’ing a roaster, though is more involved. I’m sorry, I can’t say directly what the process would be for roasters with pre-wired thermocouples, only advise that you’d need to make sure it’s safe to reroute the built-in thermocouple. i.e. Verify that its output is for display purposes only, and not somehow integrated into the internal function of the machine, or its gas/heat/timing controls -OR- find a way to safely install a second thermocouple.

I would be interested in looking at the manual – if you have a PDF version please send it over, or if you have a contact at the company and want to discuss it by phone, I’d be happy to sit in a conference call – it would be a learning process for me to familiarize myself with this particular roaster. Please let me know via email and we can continue this conversation: support@rainfroginc.com

Kind regards

Danny Hall

Here’s my question, fellow roasters and FrogTree engineers:

Reading air temp in the roasting chamber gives us the outline of the bean temp curve, but doesn’t follow true bean temp as the air buffers the delta (change) in the bean temp.

Particularly, when, during first crack, when the roasting goes exothermic, air temp reading is going to lag behind actual bean temp.

Be really nice to know by about how much, but without being able to read bean temp directly (Behmor Plus) I wonder whether and how we might determine this compensatory factor.

Also, air temp curve likely outlines the bean temp curve with a time offset as indicated in the previous observation. I wonder whether and how we might determine the temp difference between beans and chamber and, also, whether this difference remains linear or varies otherwise predictably (formula).

Anybody have any thoughts on this?

🙂 Cheers.

w68n8h